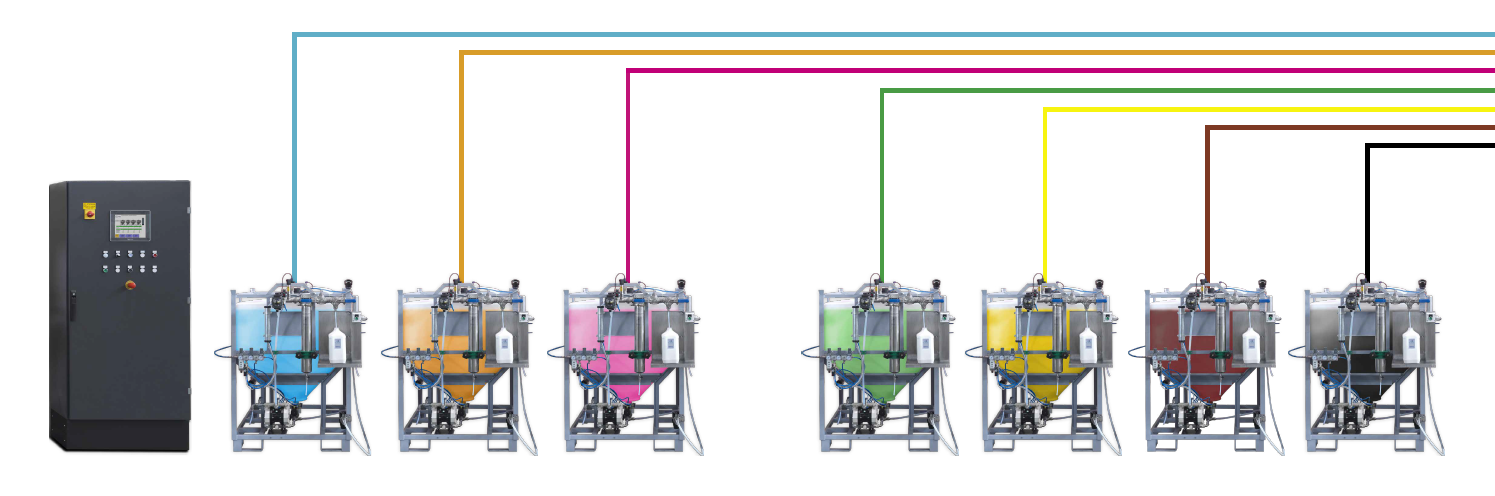

INK-FREE is our system for the automated storage and supply of inks for digital printers. A complete solution, engineered to ensure continuous operation, consistent quality, and intelligent ink consumption management.

Thanks to its recirculation system, INK-FREE keeps inks perfectly homogeneous and always ready for use.

Components of the INK-FREE System

1.

RE-FILTER

A storage tank with a self-supporting structure, equipped with an integrated recirculation and filtration circuit to maintain inks in optimal condition. Available in various sizes, from 1,300 to 2,000 liters, to meet every production requirement.

2.

KIT INK-FREE

A compact feeding module installed directly on each digital printer, ensuring correct transfer of ink from the storage tank to the printhead.

3.

DIGI-CALL

An intelligent supervision system that monitors ink levels in real time, tracks consumption, and autonomously manages recirculation and feeding to the printers. Optimizes efficiency and simplifies operations.

* The video may not appear if you haven’t accepted third-party cookies. You can adjust your preferences using the green icon at the bottom right.

RE-FILTER Tanks

The 1,300 L and 2,000 L RE-FILTER tanks can also be used as standalone components, without necessarily adopting the full INK-FREE system. These models integrate advanced storage, recirculation, and filtration to ensure inks are always homogeneous and ready for use, maintaining high quality standards even without the complete system.

Equipped with control and automation technologies such as level sensors, PLC touch panel, double-diaphragm pumps, and electro-pneumatic valves, the tanks ensure reliability and ease of use, even in lean or customized production environments.

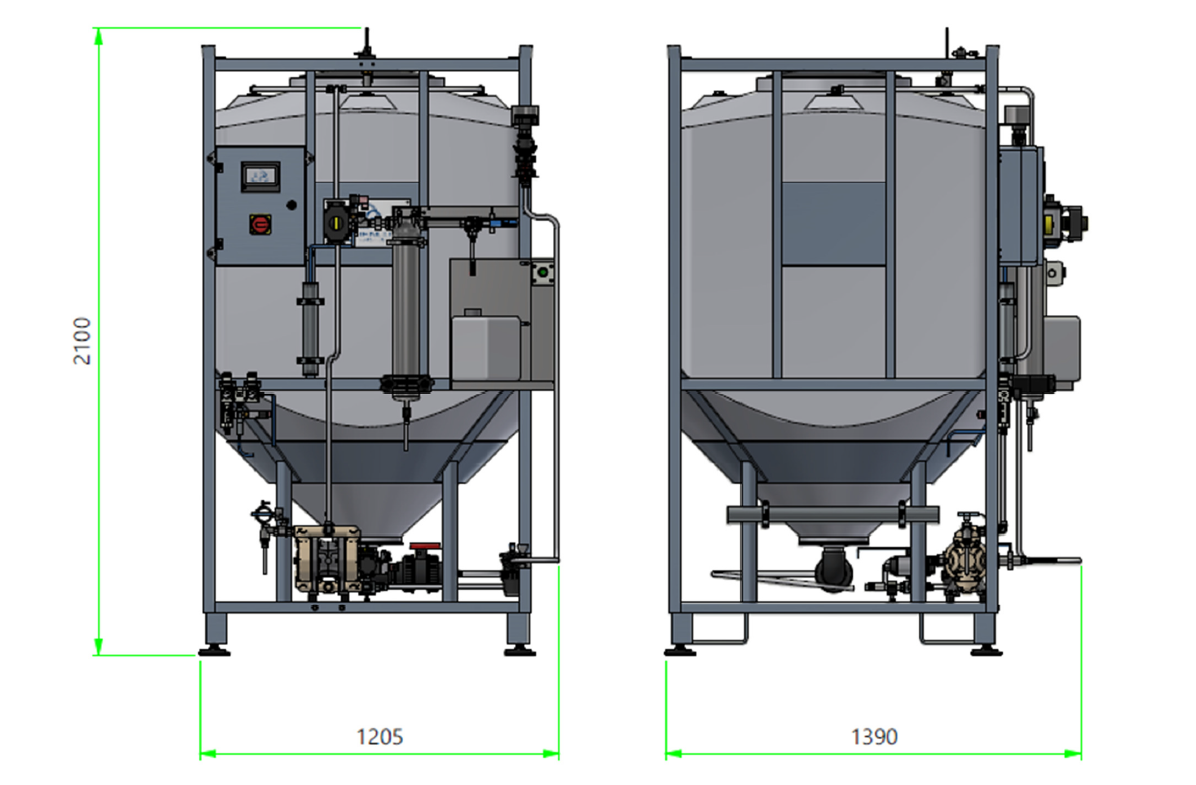

1,300 L Tank

Dimensions and Technical Specifications

| Footprint dimensions | 1.205 (W) x 1.390 (L) x 2.100 (H) mm | Electric Frequency | 50 Hz |

| Max Compressed Air Consumption | 12 Nmc/min at 6 bar | Min Ambient Temp | 10°C |

| Compressed Air Connection | Tubo Rilsan 1/4″ Rilsan tube (female threaded fitting, pos.3) |

Max Ambient Temp | 35°C |

| Max Air Pressure | 7 bar | Tank Level Control | Analog |

| Installed Power | 1 kW | Digital printer reservoirs refillable from the Re-Filter tank | Maximum of 4, each featuring 1 analog and 1 digital sensor |

| Electrical voltage | 380 V |

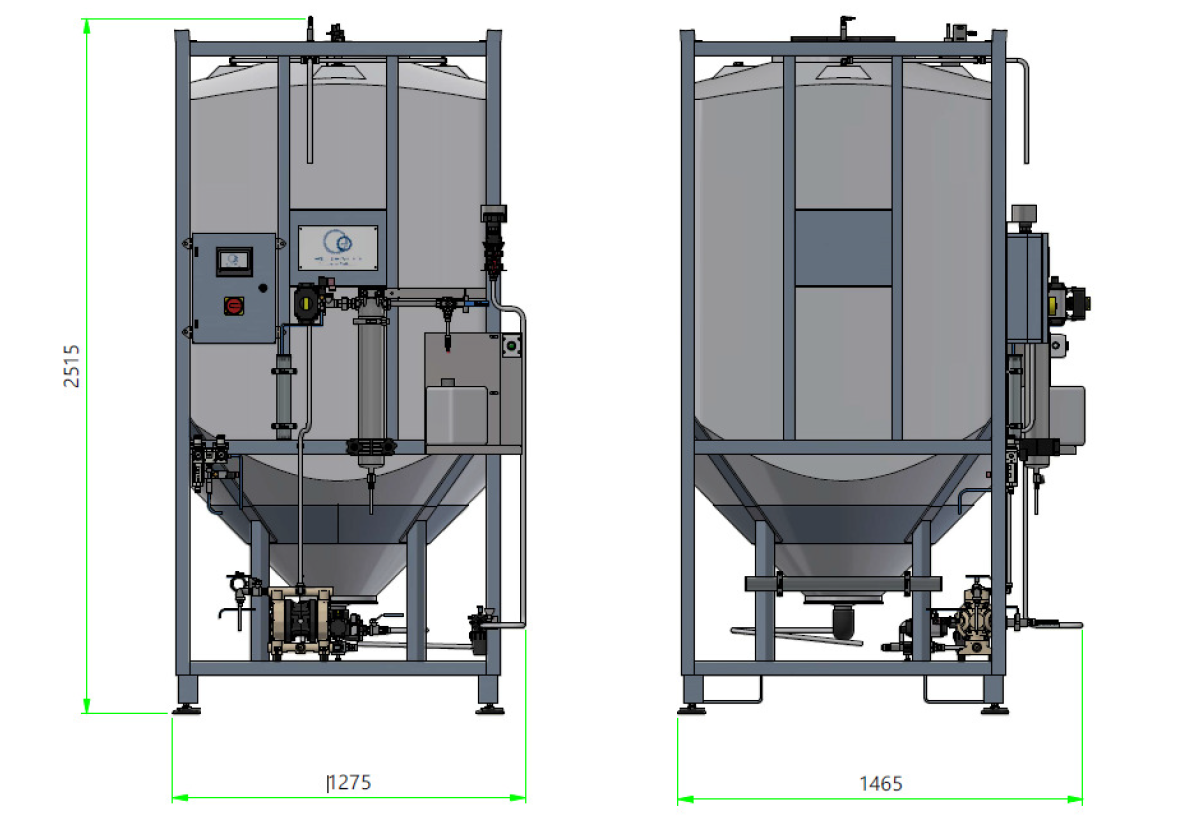

2,000 L Tank

Dimensions and Technical Specifications

| Footprint dimensions | 1.275 (W) x 1.465 (L) x 2.515 (H) mm | Electric Frequency | 50 Hz |

| Max Compressed Air Consumption | 12 Nm³/h a 6 bar | Min Ambient Temp | 10°C |

| Compressed Air Connection | 1/4″ Rilsan tube (female threaded fitting, pos.3) | Max Ambient Temp | 35°C |

| Max Air Pressure | 7 bar | Tank Level Control | Analog |

| Installed Power | 1 kW | Digital printer reservoirs refillable from the Re-Filter tank | Max. 4, each with 1 analog and 1 digital sensor |

| Electrical voltage | 380 V |

Why choose INK-FREE?

Consistent Homogeneity:

Ink always ready and perfectly mixed.

Zero Residue:

Reduces waste and improves sustainability.

Error-Free:

Automated and monitored system.

Eco-Friendly:

Less waste, more efficiency.

Cost Savings:

Optimized consumption and reduced operating costs.

Top Quality:

Stable and repeatable print results.

Active Monitoring:

Continuous control of parameters and performance.

Customizable:

Configurable according to production line and plant requirements.

Contact us to configure the INK-FREE system

that best suits your production line.

Interested in this product?

Fill out the form to receive more information.