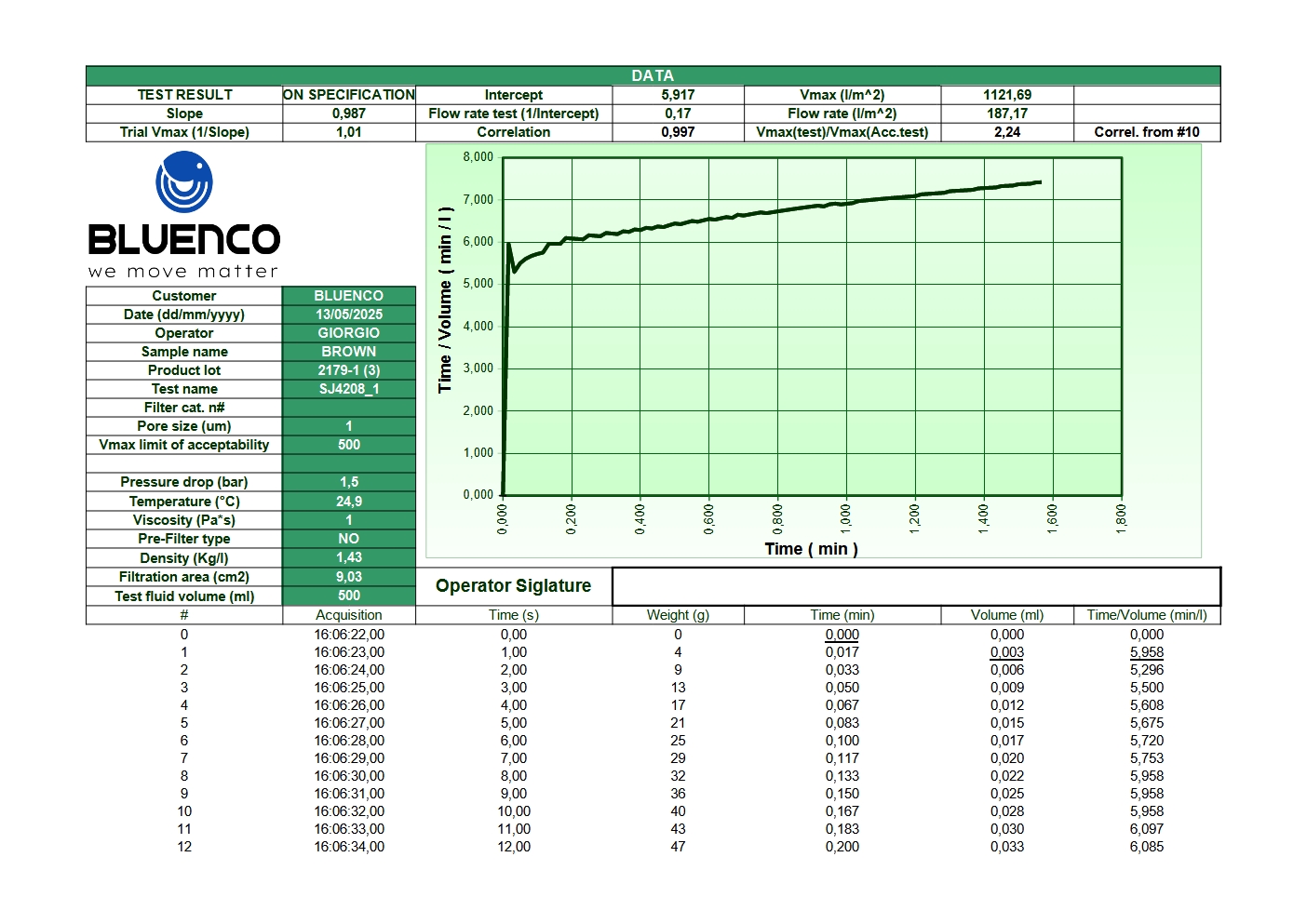

The BLUE FIT instrument measures the filterability index of inks, a key parameter for evaluating quality, stability, and suitability for industrial filtration. The Vmax value, obtained through testing, determines the maximum volume of ink (L/m²) that can pass through a filter surface before it becomes fully clogged, depending on the filter micron rating. This data allows assessment of filter clogging and supports the proper definition of filtration parameters.

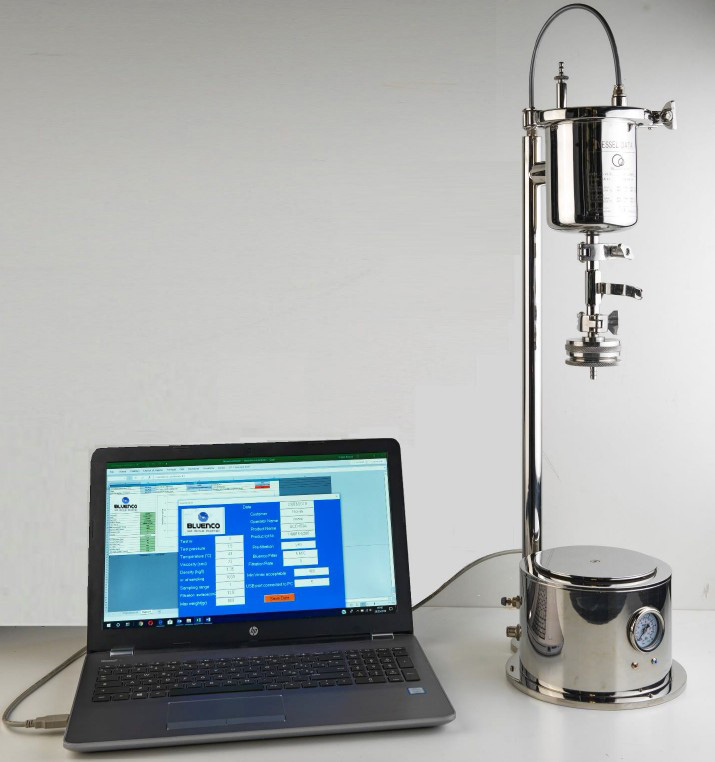

The system includes a stainless steel tank, dedicated filter, portable scale, and Windows-based software for data acquisition and processing.

Compressed air regulation and weighing management unit in a single integrated device

• Inlet and outlet connections for compressed air

• Pressure regulator 0–2.5 bar

• Pressure gauge 0–2.5 bar

• 24 V on/off valve

• Unit for weight acquisition and regulation of compressed air flow (inlet and outlet)

Polished stainless steel tank, mirror-finished inside and outside, 1 L volume, complete with 4” sealing cap, Viton O-ring, manual valve to stop dripping during filter replacement, and 47 mm filter used for testing.

Filter housing for 47 mm filter

Load cells (0 -15 kg)

Software for instrument operation and Windows-based data acquisition

BLUE FIT Filterability Index Control Instrument

| Technical Specifications | |

|---|---|

| Tank | Stainless steel, polished, 1 L |

| Filter | 47 mm diameter |

| Regulation | Integrated compressed air unit |

| Weighing | Portable scale (0–15 kg) |

| Filter Holder | Rubber + stainless steel extensions |

| Software | Windows-based data acquisition |

| Valve | Manual for drip stop |

Interested in this product?

Fill out the form to receive more information.