Our Refurbishment Process: Inspection, Cleaning, Restoration

Each printhead undergoes a rigorous, multi-step process:

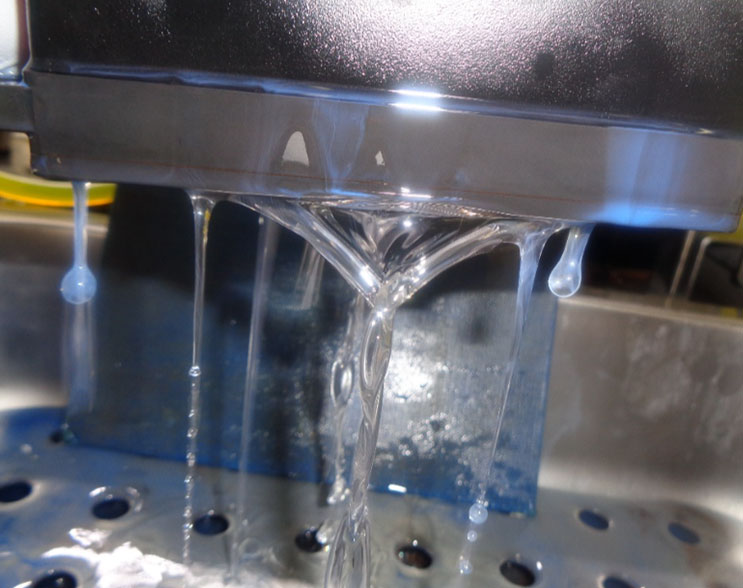

REAL CASE

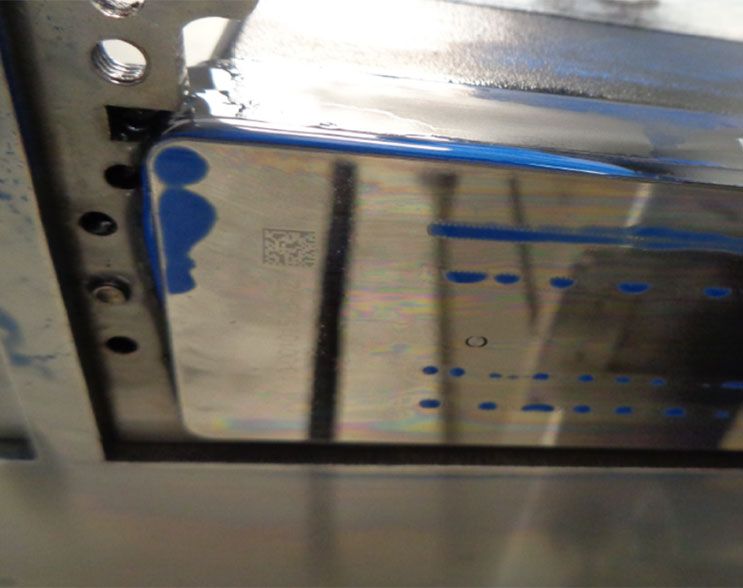

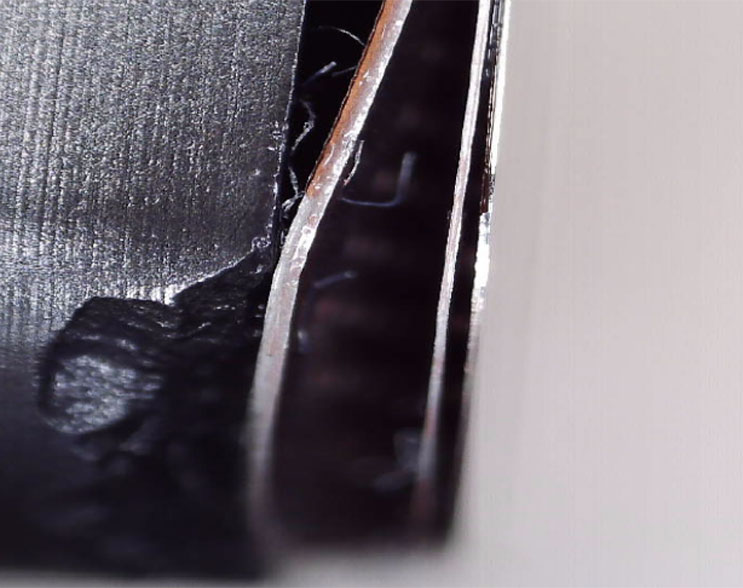

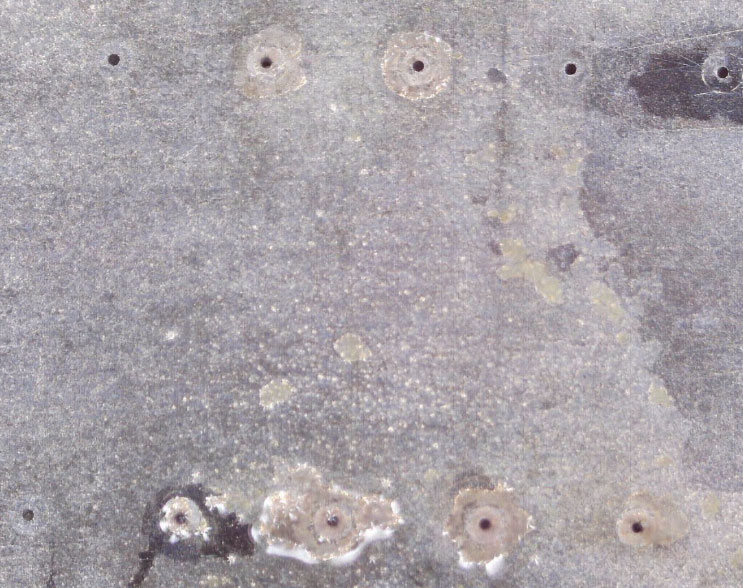

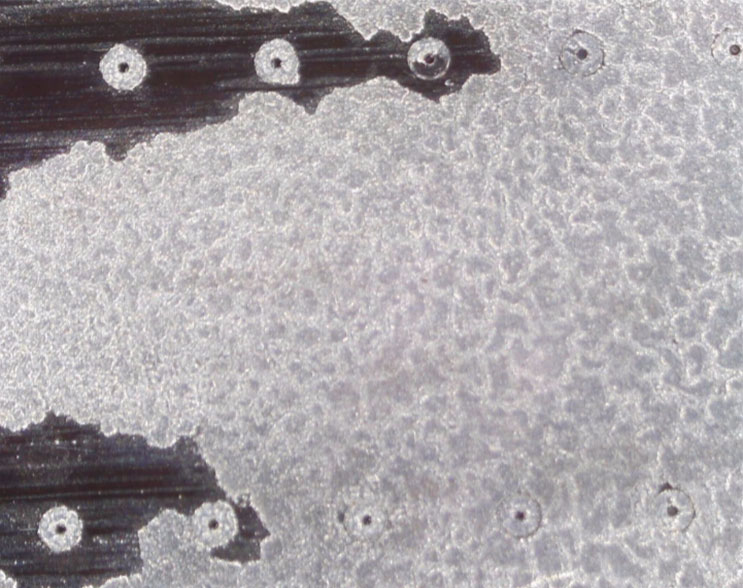

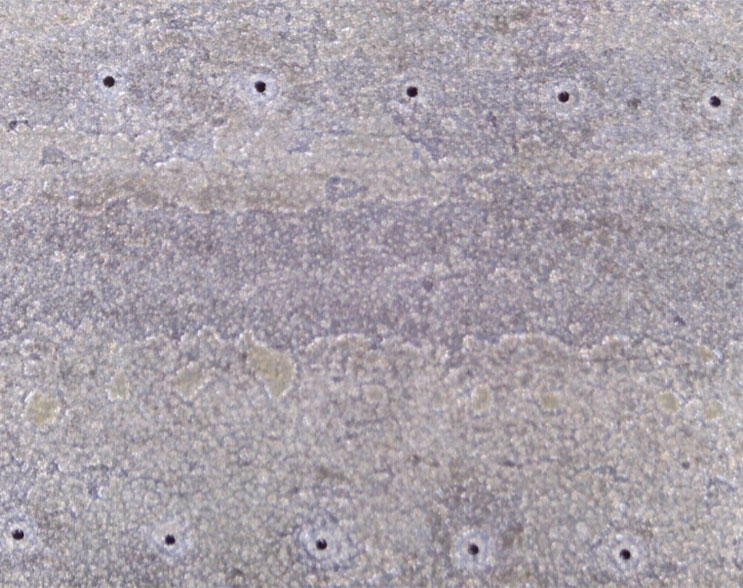

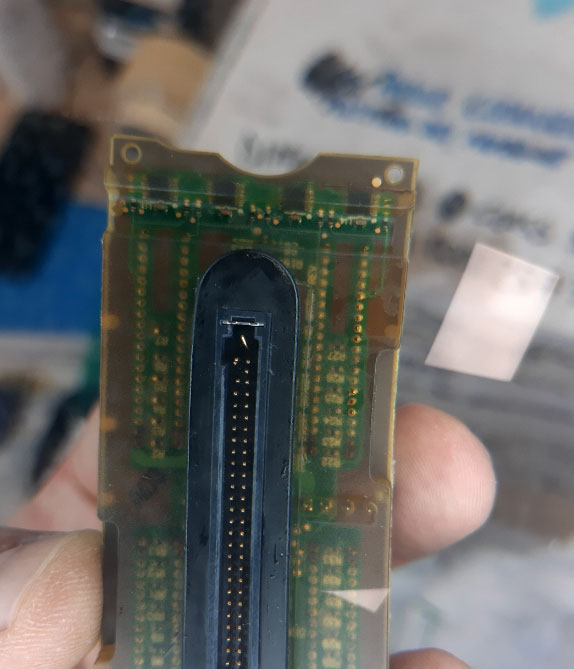

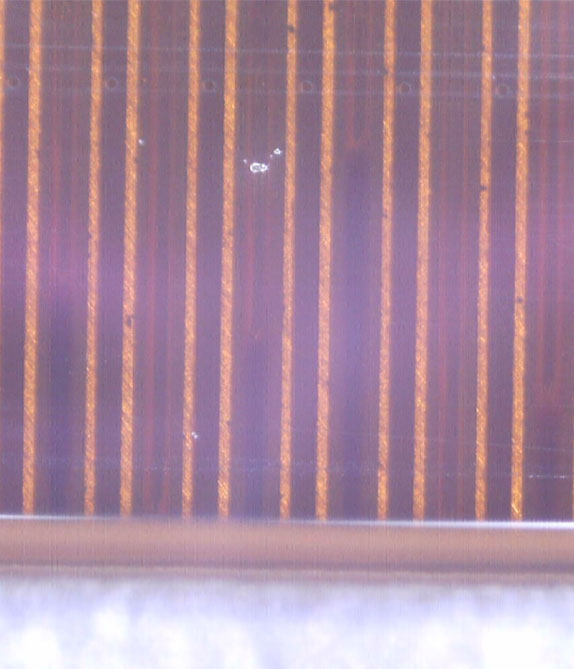

The Before, During, and After of a Refurbishment

To concretely demonstrate the effectiveness of our intervention, here’s a real example of the results achieved on a printhead refurbished by Bluenco:

Common Issues Identified in Printheads

During testing and cleaning, our technicians often encounter issues that affect functionality. Some of the most frequent problems include:

Not all issues are fully repairable, but Bluenco identifies every anomaly and recommends the most effective and sustainable solution for the client.