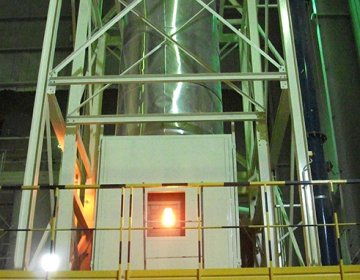

Frits are usually the main ingredient of ceramic enameling. They are produced by high temperature melting of the diverse components in specific

kilns, whose final produce is a white-hot liquid which is then cooled down.

BLUENCO designs and engineers kilns to match the specific needs of our customers and the overall installation in which the kiln will be placed,

aiming to ensure lower production costs. The right decisions during the design project can heavily impact the ROI time frame.

We carefully analyze kilns production capacities, specific thermal consumptions, production stop frequencies, firebricks wearing, exchanges frequencies, availability and quantities of raw materials, frits specifics. Then we select the appropriate solution among those available:

- kiln size and shape

- refractary materials quality

- single or multi-burner combustion plants

- combustion plants fuelled by gas and air, oxy-combustion, gas and

- oxy-combustion, heavy oil and air, coal gas and air

- fixed or tilting kilns

We design every project while carefully measuring and monitoring any variation in sensitive parameters (gas costs, firebricks costs, raw materials costs, etc), which dramatically change depending on the geographical area, and in time, then we analyze all data through our experience.

BLUENCO also provides kilns revamping solutions for any type of existing kiln. Revamping allows us to overcome design and technology limits of the past, by integrating modern and state of the art solutions with the original project. This ensures a smaller investment than a new built would require, while at the same time making the whole system more efficient.

Thanks to our team’s ten-year experience we can offer turnkey plants, from foundations (civil engineering) to product storage, including all

departments (compressed air production, water cooling, reception, transformation and redistributing of electrical power). We also provide on

demand analysis of customers’ raw materials, at our labs, employing our know-how to provide improvements in the way raw materials are used.

BLUENCO also designs, produces and installs a wide range of complementing products for kilns, such as feeding screws, combustion systems, heat exchangers, vibrant cooling tunnels, cool vessels for frits extractions.